Restoration

RESTORATION PROCESS AT HACKER-CRAFT

Our world-renowned craftspeople regard each restoration project as though the boat is their own. Their work reflects the their attention to care, quality and detail that an owner would show their own boat.

Our team’s knowledge and skills are extensive regarding every aspect of the restoration process. They will restore your boat to its original condition or make improvements to return it like new, while assuring it has the latest advances in materials and technology…all with your approval for each step of the process.

Our restoration team and boatbuilding team are one in the same. The same craftspeople work diligently on restoration projects with the equivalent quality as building a new boat.

Estimate

Our restoration manager will review the services that you request and perform an evaluation of the boat, virtually or on premise. Next, he will provide a recommended scope of work, including a general estimate of the overall cost and timeframe needed to complete the project. Our naval architect reviews all the estimates for accuracy and can work closely with clients to implement design modifications to existing boats.

Delivery

We will arrange pick up delivery of your boat using trusted transportation services.

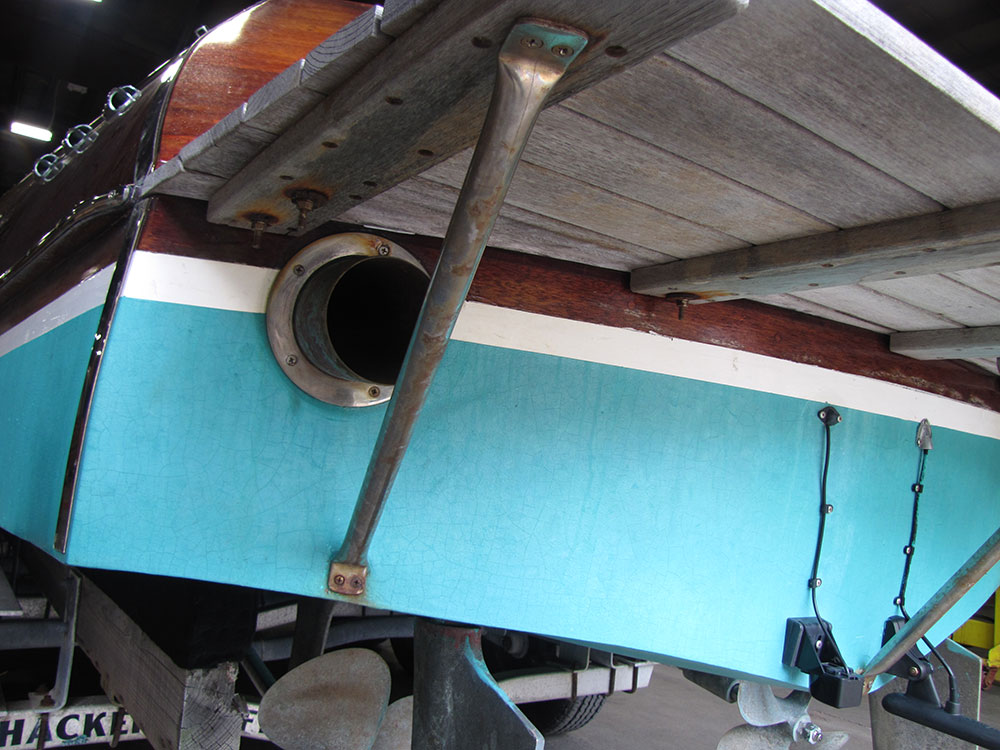

Survey and Inspection

After arrival at our restoration facility, our manager and foremen will review the work order. They will also perform a thorough survey of your boat, including hull finish, engine, transmission, rigging, hardware, and upholstery and will advise if any additional work is needed.

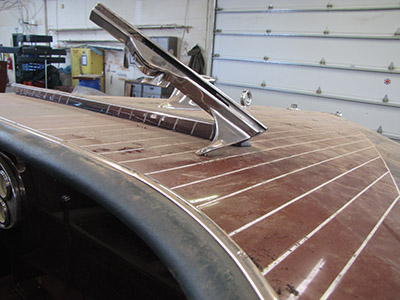

Wood

The hulls, decks and other wood components are inspected to determine the condition of the structure and the finish. Wood can be replaced or refinished as needed. All damaged or rotted wood is replaced with genuine mahogany and equivalent hardwoods. Every wood component of the boat, notably the stringers, will be checked for stability. The West System is used to protect the wood and ensure a minimal prospect of leaks.

Interior

The boat’s interior parts, including seating, cushions, upholstery can be restored or replaced using the original materials or materials with advanced protection capabilities. Our team makes every effort to match new and existing materials to improve its appearance, while maintaining the boat’s classic aesthetic. All upholstery work is performed on site in our upholstery department.

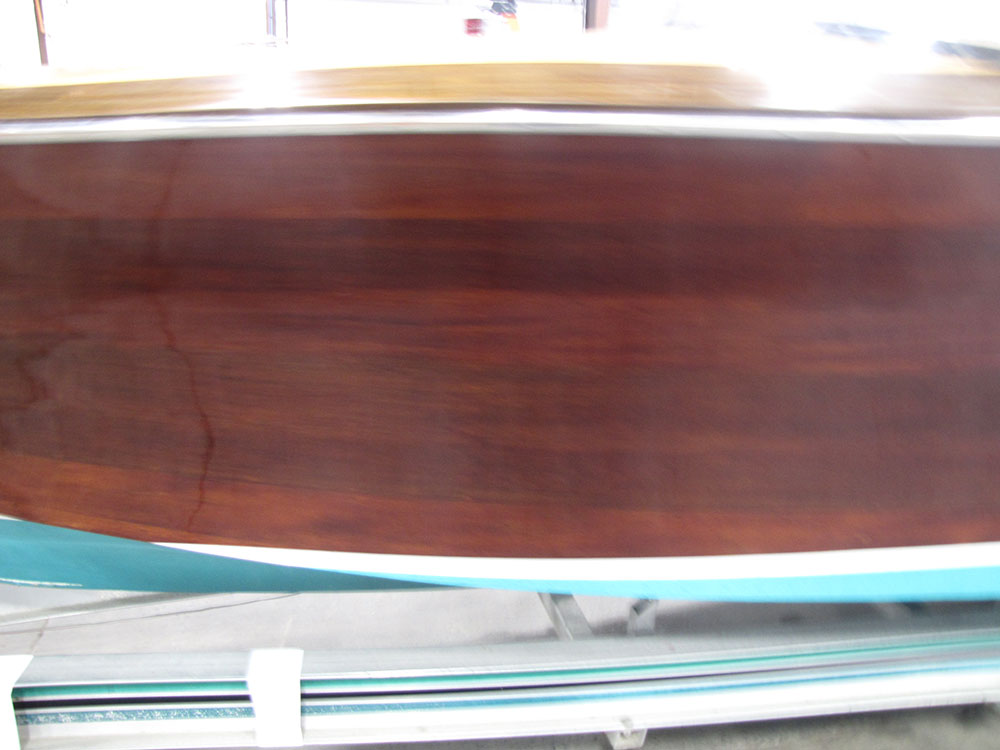

Finish

The brightwork finish is the most notable and relevant step in the restoration process. Whether completely refinishing the varnish surfaces with new stain and 14 coats of varnish, or simply refreshing the top 2 coats of varnish to maintain your Hacker-Craft’s mirror-like shine, all layers are applied by hand.

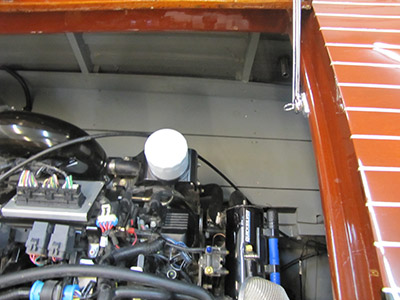

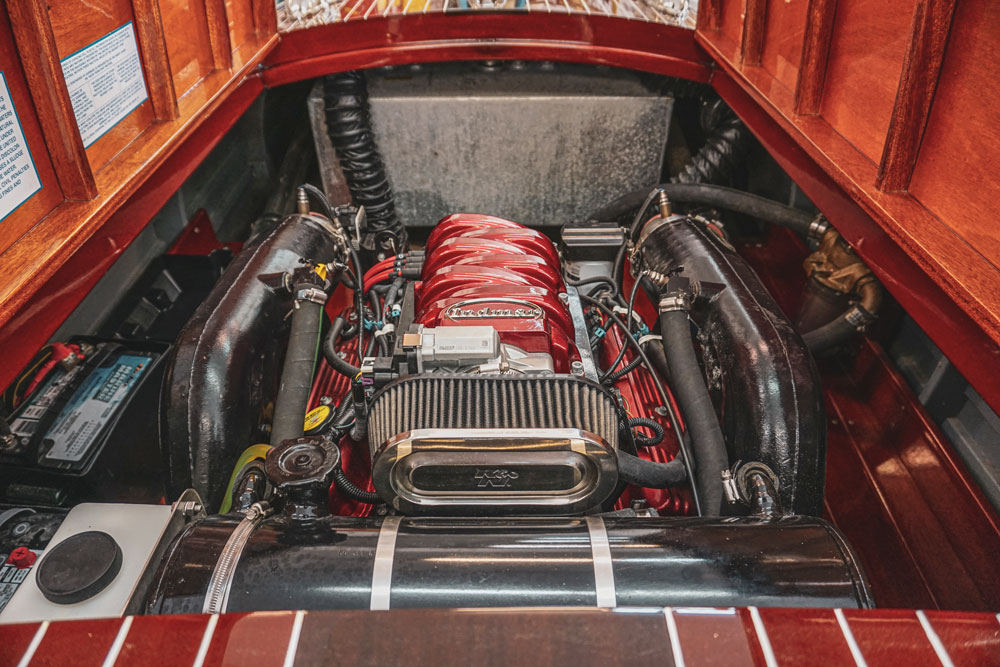

Engine and transmission

Our team can perform an engine and transmission service. Any further extensive work will be determined and disassembly and rebuilding can be addressed as necessary. If needed, recommendations for replacement units may be provided. Additionally, the engine and transmission performance are measured by a water test or diagnostic equipment, with the findings documented.

Customer Service and Completion

Our Production Manager stays in touch with you and regularly updates you on the status of your project and shares progress photos throughout the process. Upon completion of restoration services, your boat is returned to you in superb condition with a detailed description of the project services.

- Hacker-Craft

- Chris Craft

- Lyman

- Fay & Bowen

- Garwood

- and more…